Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

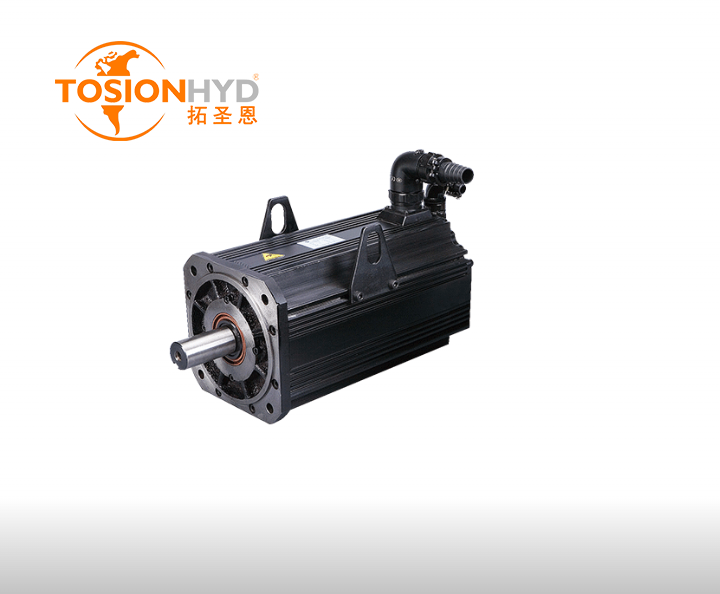

Hilectro HS SERVO MOTOR LIQUID COOLING FOR TEXTILE DIE CASTING ALUMINIUM INDUSTRY

As liquid cooling motor, HS series servo motor can adopt water cooling or oil cooling as the cooling method. It is developed for the textile factory, die casting factory and aluminum plant to use under severe environment.

Product Features

High performance

The rotor magnetic steel of the motor is made of high performance NdFeB permanent magnet material (the temperature resistance is up to 180℃). The motor has the advantages of small size, high efficiency and quick responding.

Good applicability

According to different customer requirements, the motor can be designed for instantaneous 2-5 times overload with good applicability.

Good cooling effect

Spiral design is used for the coolant pipe of the motor, which is with large coolant contact area, large diameter and thus has a good cooling effect.

Safe motor shell

The motor shell is made of seamless steel tube, and the cooling water channel is completely isolated from the electrical part inside the motor. Even if the water channel is damaged outwards, it can be guaranteed to be isolated from the charged body without damaging other parts of the motor.

Safety standards

Comply with CE and UL safety standards.

Applications

Hydraulic servo system

Suitable for hydraulic press, aluminum extruder, die casting machine and injection molding machines.

In these devices, the HS servo motor drives the hydraulic oil pump to maintain the required action by PID regulation of the output pressure and flow. This system provides flexible control and stepless regulation, which helps to reduce oil temperature and improve efficiency.

Mechanical servo system

Mainly used for servo punch, servo press and other equipment requiring high precision and high response.

It is applied to blanking, stretching, forming, bending, stamping and other processes. The servo motor directly provides power, and converts the power into linear motion of slider through screw rod, crank connecting rod and elbow rod.

Custom Solutions Available

Need a custom hydraulic solution for your production system? We offer OEM & ODM services tailored to your needs.

Looking for a trusted hydraulic parts supplier for your manufacturing system?

Contact us today for pricing, MOQ details, and lead times. Our team is ready to assist you with sourcing the right hydraulic components for your needs.