Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

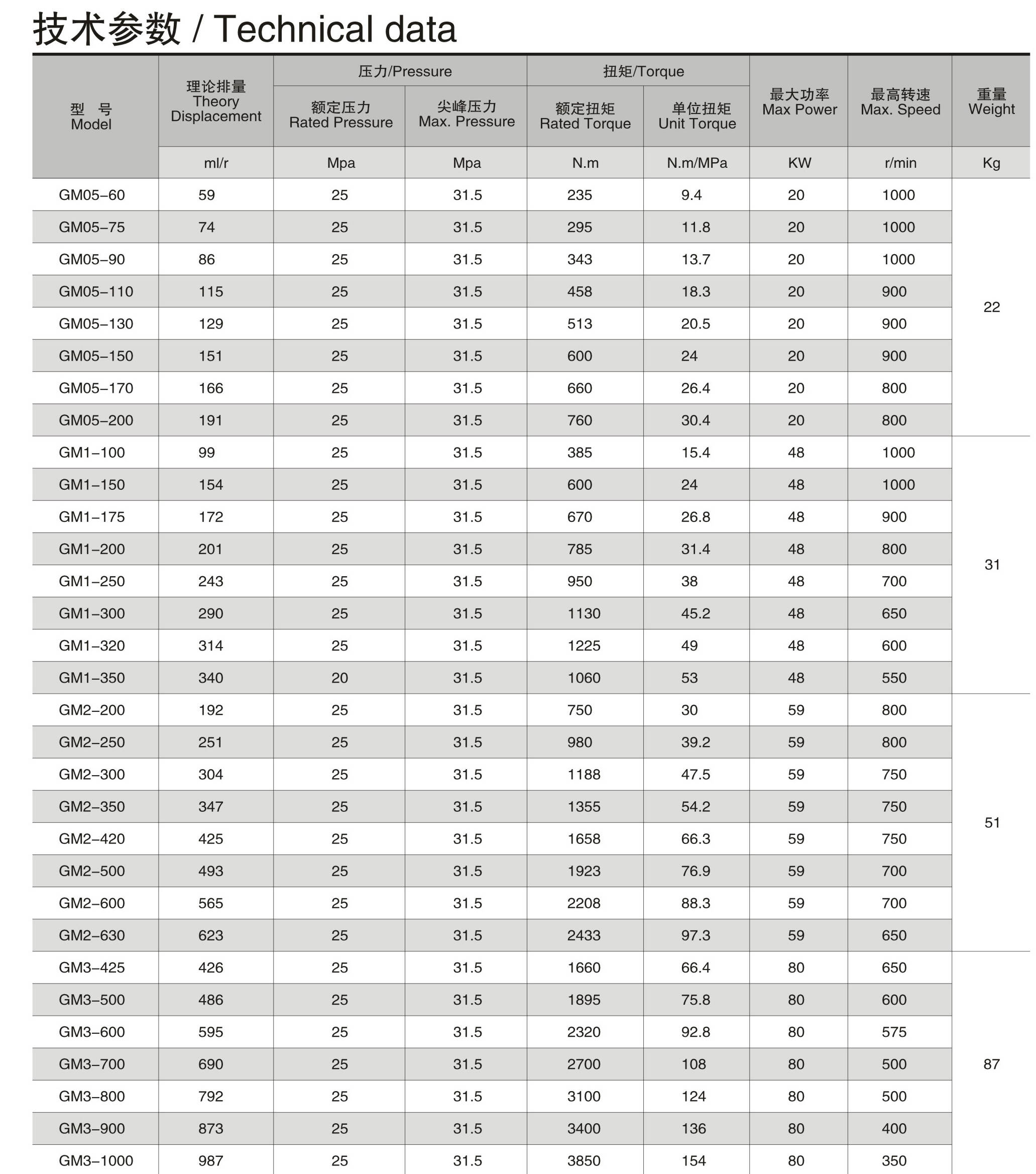

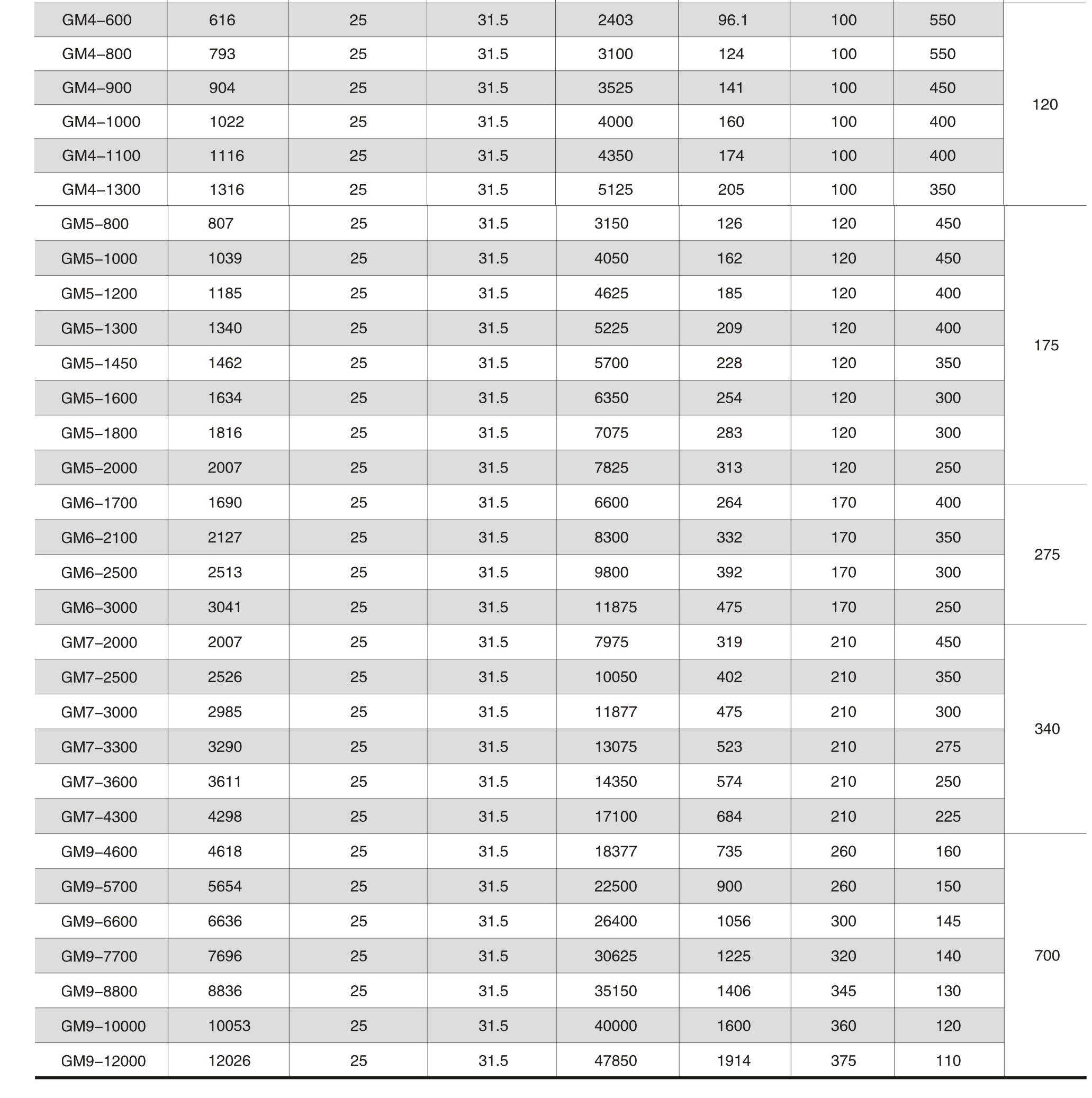

SAI HYDRAULIC GM MOTOR GM05/GM1/GM2/GM3/GM4/GM5/GM6/GM7/GM9

The GM series hydraulic motor is designed for superior mechanical efficiency, high startup torque, and exceptional durability. With a unique static pressure balance design, patented plane distributor, and low-friction bearing system, it ensures smooth operation even at 1r/min. Ideal for heavy-duty applications, this motor offers high pressure resistance, compact size, and long service life, making it perfect for industries like construction, metallurgy, agriculture, and marine engineering.

*Above data sheet just as reference, please contact us for more details.

Product Features

High Mechanical Efficiency (Over 0.92 at Startup)

The GM series motor minimizes friction loss by using rolling bearings between the piston and crankshaft, ensuring high torque transmission efficiency and smooth performance even under heavy loads.

Advanced Seal Technology (Volumetric Efficiency Up to 0.98)

Equipped with a patented plane distributor and plastic piston rings, this motor provides near-zero leakage, enhancing energy efficiency and reducing maintenance costs.

Exceptional Low-Speed Stability (Operates at 1r/min)

Thanks to optimized pressure balance and reduced internal friction, the motor delivers stable performance at ultra-low speeds, making it ideal for precision applications.

Reversible & Durable Design

The motor supports bidirectional rotation and can withstand radial loads, ensuring long service life in demanding environments like mining and construction.

Multiple Shaft Options for Flexible Integration

The GM1 to GM9 hydraulic motors are available with three shaft configurations: rectangular external spline, splined shaft, and keyed shaft (flat key). This versatility ensures seamless compatibility with different transmission systems, allowing for easy installation and customization based on your machinery requirements.

Applications

Construction Machinery: Excavators, loaders, and cranes requiring high torque and reliability.

Agricultural Equipment: Harvesters and tractors needing durable, low-speed operation.

Marine & Offshore Systems: Winches and propulsion systems with corrosion-resistant performance.

Industrial Automation: Plastic injection machines and conveyor systems with precise speed control.

Mining & Metallurgy: Heavy-duty drilling and lifting equipment under extreme conditions.

Custom Solutions Available

Need a custom hydraulic solution for your production system? We offer OEM & ODM services tailored to your needs.

Looking for a trusted hydraulic parts supplier for your manufacturing system?

Contact us today for pricing, MOQ details, and lead times. Our team is ready to assist you with sourcing the right hydraulic components for your needs.